Consider: Birkenstock

A real corker

This week, Considered was featured on Substack’s homepage and we are very excited to welcome 100+ new readers! Hopefully you like what you read. You can access back issues of Considered here: https://considered.substack.com. Some classics from the archive include Jared’s juicy dive into Sumo Oranges (only a couple weeks left in the season) and a history of the Nalgene (a Reddit favourite). Feel free to hit reply and introduce yourself!

In past issues of Considered we’ve explored many companies who have achieved longevity and iconic status while remaining family owned and operated (ie. Walkers Shortbread, Ritter Sport, Lodge Cast Iron). I got nervous when I heard that the classic footwear company Birkenstock would be selling a controlling stake in the family owned firm, +200 years after the family first started making shoes. Would the magic fade? Especially because they were selling to a private equity firm, L Catterton, controlled by B Arnault, the French billionaire who also controls the world’s largest luxury goods company, LVMH (Birkenstock and Louis Vuitton are now siblings!). I decided to dig in to find out more. Lucky for me (and you), the backstory of Birkenstock’s practical and sustainable footwear, aligns well to the Considered mental model of exploring, Well Made and Well Lived objects and stories. I promise this is not another hot-take on if Birkenstocks are fashionable.

Design

Members of the Birkenstock family were German cobblers going back to at least 1774. By the early 1900s, Konrad Birkenstock grew from having shoe shops in Frankfurt, to starting a factory to produce his popular insoles for shoes, ultimately leading him to coin the term “Fussbett”... the original footbed. According to the company, it was a “new approach in shoemaking: the idea of a flexible, supportive insert that, with minimal effort, made every shoe comfortable and healthy.” Up until this moment, insoles were flat or designed to fix an ailment. No one was designing insoles for mass comfort.

After becoming well known for publishing and teaching his orthopedic philosophies (over 5,000 Carl Birkenstock System disciples took his week long course), Birkenstock integrated the footbed into a sandal in 1963. The core design elements were a footbed made of cork and latex (that replicated the footprint of a healthy foot walking in the sand) combined in a natural material sandwich of suede and jute, all on a durable sole. This core design and construction has largely remained the same over the past 50 years.

Innovation

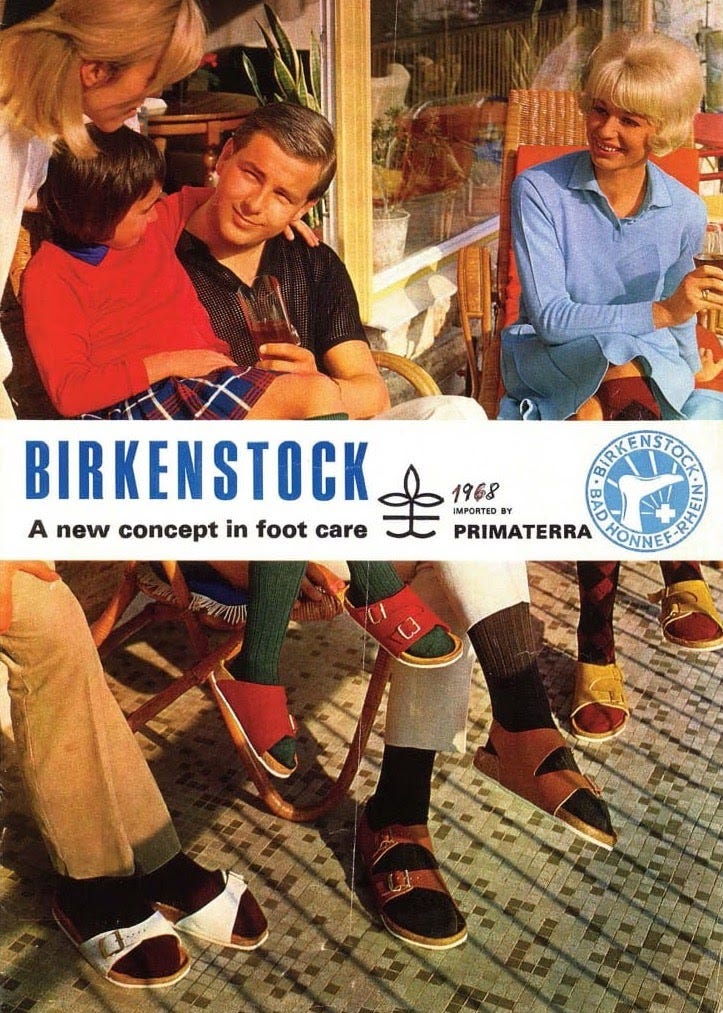

Birkenstock was a pioneer when it combined athleisure AND wellness elements into footwear. When the first, and now iconic, Milan sandal model was launched in 1963, Birkenstock called it the “Gymnastics Sandal” because “the grip reflex of the toes is activated when you walk, exercising your foot and leg muscles” all while delivering comfort. The sandals were actually part of the first athleisure trend in the US. Other than Chuck Taylors (from Converse), there were not many options for people who wanted shoes that fit a more laid back and comfortable lifestyle.

Margot Fraser was an American visiting a spa in Germany in the 1960s when she tried Birkenstocks for the first time and fell in love. She reached out to then CEO, Karl Birkenstock, to get the rights to the US market. The shoes were considered so ugly that mainstream shoe stores refused to sell them. Fraser only found success when she convinced health food stores to stock them. More than 40 years later, TOMS Shoes would find similar success being distributed through Whole Foods.

Until very recently, Birkenstock was very resistant to design for fashion’s sake. The brand has always tried to position its design as being functional and supportive of good foot health. Current CEO, Oliver Reichert says,

“If you talk to Karl Birkenstock, 82 years old, sitting in his house in Austria, getting more and more negative, he is the godfather of this absolutely design-hating, anti attitude — to say that nothing is designed. It’s about function.”

Since the 1960s, Birkenstock has taken the same classic footbed and expanded its use across dozens of styles. However, as of 2019, three classic designs, the Arizona, Milan, and Gizeh, still accounted for +50% of sales. The company has also expanded into new footwear categories like clogs, casual shoes, boots, and even a Professional series with steel toes and safety certifications, all while keeping the classic footbed as a core element and striving to make every style recognizable as a “Birkenstock”.

Not content with only in-house innovation, Birkenstock has pursued innovation through collaborations. In 2019 they opened a Paris based office called “1774”, as an “incubator for developing innovation and new partnerships” with other brands. Since then they’ve released surprising collaborations with fashion brands including, Rick Owens, Valentino and Stussy.

Sustainability

Most of the materials that go into a Birkenstock sandal are natural (cork, latex, jute, leather/suede), with the majority being renewable. Birkenstock prides themselves on sourcing their materials sustainably and, when possible, from European sources close to their manufacturing facilities in Germany, where all their products are still made. In hindsight it seems obvious, but I was amazed to learn about the supply chain journey of the cork they source through this video. The basis for their footbeds comes from cork that is hand harvested from trees in Portugal. While this cork is primarily used to make wine stoppers, the leftover offcut cork remnants are ground up to make Birkenstocks. Cork as a supermaterial has a new place in my heart, next to merino wool.

In recent years to manage price points and cater to changing consumer preferences, synthetic material uppers are also now available, in place of the traditional leather. They even offer a Vegan line of sandals that look identical to their traditional models and happen to cost less!

If you want a meditative and somewhat abstract view behind the scenes of what the Birkenstock production process looks like, you’re in luck. Famed German photographer Jeurgen Teller shot their Görlitz factory to accompany an article for The Cut.

Value

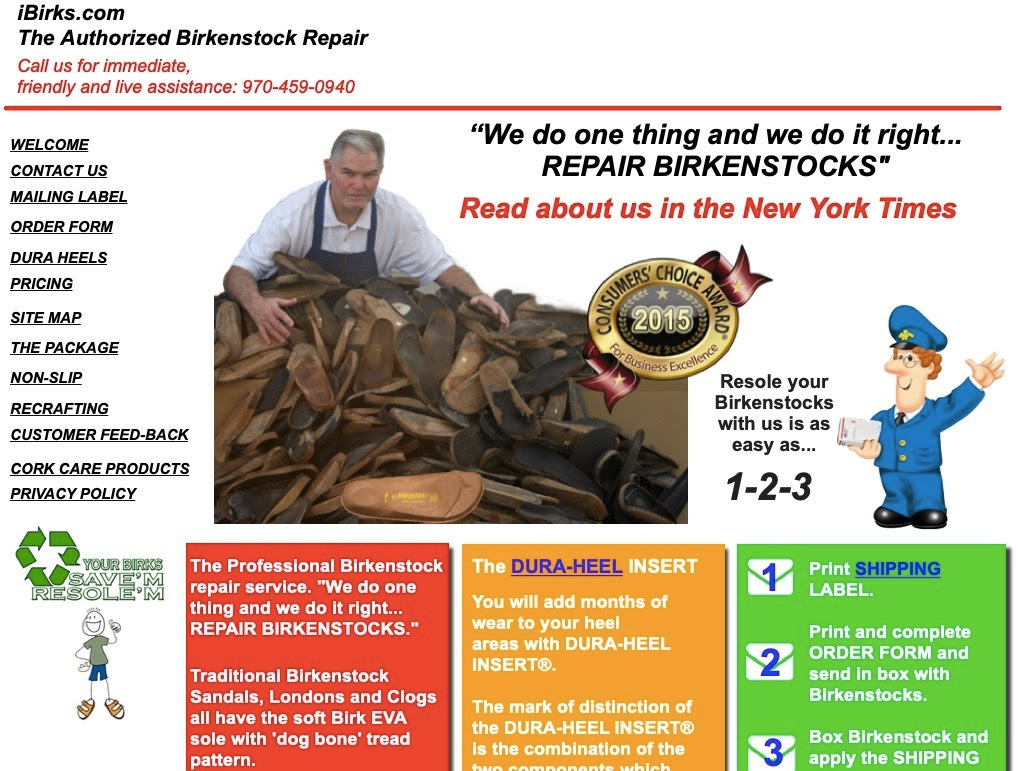

In previous editions of Considered, we’ve also highlighted when an object is designed (and encouraged!) to be repaired or have worn elements replaced. Birkenstock fully supports the logical and longstanding tradition of basic footwear repair. Check out this video if you are interested in seeing how a cobbler can recraft a pair of Birkenstocks using official footbeds and sole materials. Full replacement or recrafting of the footbed and sole can run ~$80-100. Even though all you end up keeping is the leather, the buckles and the memories, it remains cheaper (and more sustainable) than unnecessarily throwing away the whole thing. Jared reports that he has re-soled one pair of Birkenstocks at least five times. Weird flex, but OK.

At ~$120-170 per pair of standard model sandals, Birkenstocks are by no means “cheap” but are also not a luxury good. They straddle that zone of well made and reasonably priced for something that, if maintained or repaired, can last for decades.

Keeping in mind consumers looking for even lower price points, in 2015 Birkenstock developed and released a range of sandals made entirely from a single piece of EVA (ethylene vinyl acetate) that unlike traditional materials is ultra lightweight and can get wet. At $40-50/pair they deliver the same form for a fraction of the price.

Thanks for coming along this week! If you enjoyed this issue of Considered, hit that 🖤 below or leave a comment.

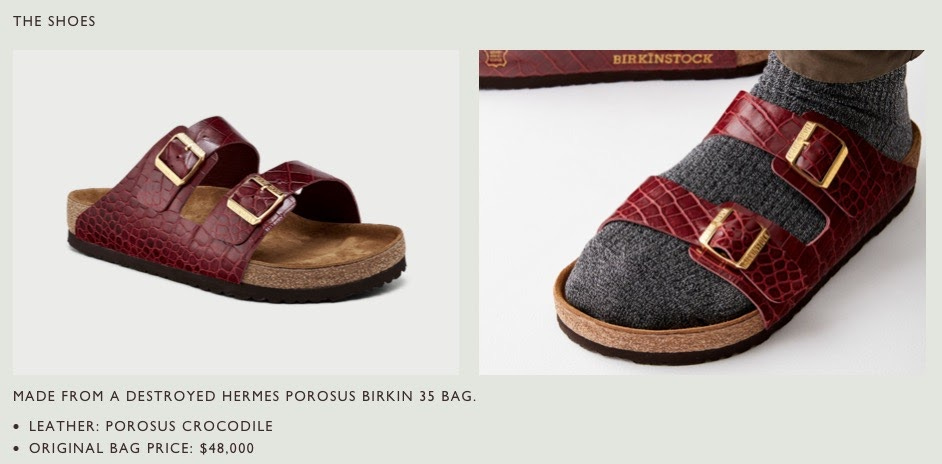

As a reward for making it all the way to the end, enjoy this video and article about Birkinstocks. As highlighted earlier, Birkenstock has explored many official collaborations, but it was a recent unofficial collaboration that caught our eye. “MSCHF”, a “motley crew of artists, designers, and product developers (that) have decided to make their mark on the internet” decided to craft “Birkenstocks Made From Destroyed Birkin Bags”. They sourced ~$48,000 Hermès Birkin bags to cut them up to craft custom Birkenstocks with a price tag of $19,000 to 48,000 per pair! For more on this project and to order your very own pair (sadly no referral code), check out: https://birkinstock.shoes