Consider: Nalgene

From the Science Lab to the Backpack

Thank you to the +70 subscribers who have joined since last week and the +170 total subscribers who have joined us so far!

The first time I ever saw a Nalgene bottle was around 20 years ago when a university housemate had one permanently carabiner-clipped to his messenger bag. I remember his bottle having a unique patina of stickers and scratches earned from laying on the ground at the latest mountain bike event or from a summer spent tethered to a whitewater canoe in the Canadian north. The bottle told a story of adventure, function and durability.

I purchased my first Nalgene when I was packing for my own whitewater canoe adventure and needed something that was light, indestructible and never leaked. Nalgene promised to do all that for only ~$15. I was sold. While my bottle never quite developed the same patina as my friend’s, it did live up to its durable and practical reputation. Had I not accidentally left it behind in a field after 10 years of service, I’m sure it would have lasted for at least another decade.

When I was replacing it, I was curious what the Nalgene backstory was. How had it become so commonplace? What exactly was so special about its design that made it so enduring?

I was surprised to learn of Nalgene’s humble origins and twisted path from the science lab to the bag.

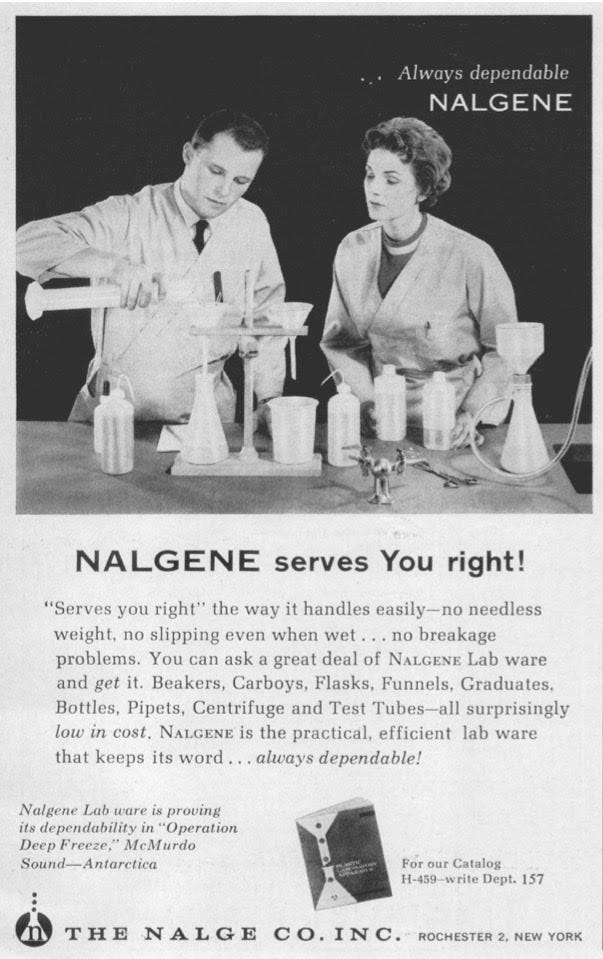

Design

In 1949, in Rochester, New York, chemist Emanuel Goldbery developed the first plastic pipette (science eye droppers) for his laboratory. He then founded the Nalge Company and expanded from pipettes to producing plastic lab bottles. The plastic material was more durable than traditional glass, while the screw tops worked well to contain liquids and odours. It was practical in the lab and even more so for scientists working outside in the field. One important thing to keep in mind is that at this time, the world was just starting to move away from Bakelite and rubbers to petroleum-based plastics, which were a relatively new invention. Plastic would not have been a common sight in the home or office.

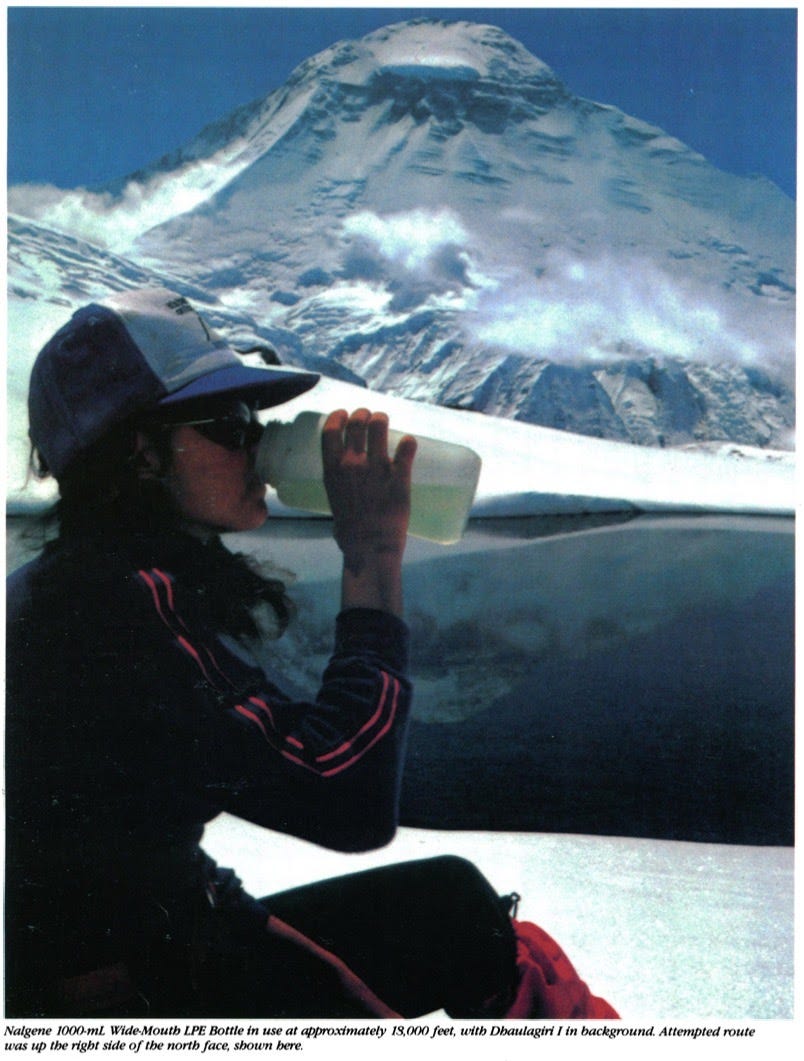

Just over a decade later in the 1960s, outdoorsy lab scientists started taking their plastic labware with them on back-packing trips because they were unbreakable, leak-proof and lightweight. The popularity of reusable containers grew in the 1970s as the Leave No Trace philosophy was embraced and groups like the Sierra Club began discouraging campers from the previously common disposal practice of burning or burying cans or glass canisters. Around the same time, the President of Nalge Company saw his son using the containers on his Boy Scout trips and had the idea to market the polycarbonate bottles as high-quality camping gear. The “original water bottle” was born.

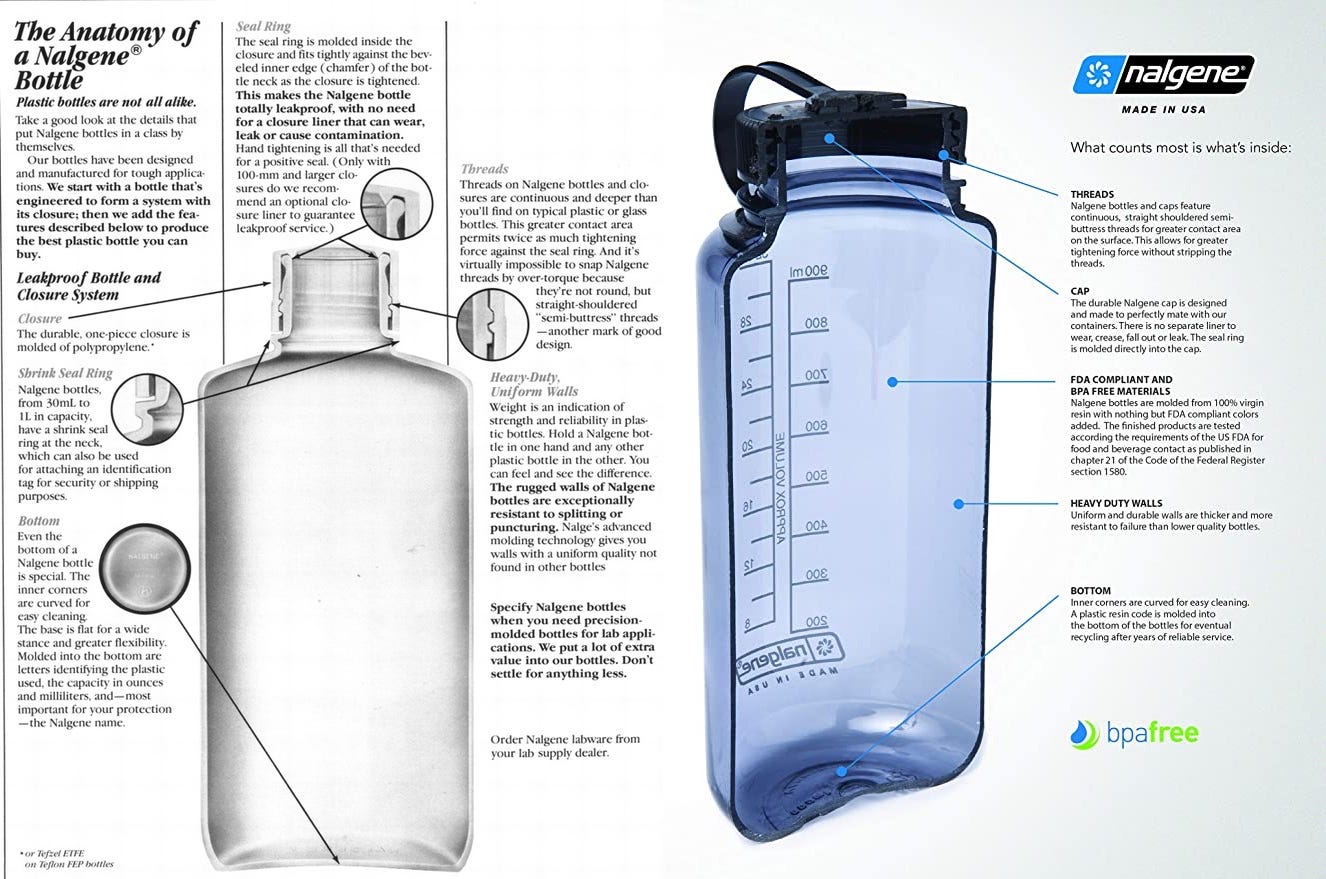

Over time the name Nalge morphed to Nalgene and the Laboratory division has continued to produce a wide variety of products for lab use, but the Outdoor Products (consumer) division is responsible for the proliferation of the classic 32 oz wide mouth bottle. You know the one - wide mouth with an attached plastic screw top and the volume markings on the side. With a slightly rounded base and wide shoulders, it’s stable, easy to clean and has an easily identifiable silhouette. But the design details that set it apart from the other water bottles are hidden under the cap: the Seal Ring and Threads. On Nalgene bottles, the seal ring is molded directly into closure and cap, eliminating the need for a liner or gasket. This avoids the risk of liner failing due to time or temperature, while keeping it securely closed and leak-proof. The threads of a Nalgene bottle are “straight shouldered semi-buttress” in design, that allow for “greater contact area… (and) tightening force without stripping the threads”. The straight continuous threads perform better than partial rounded threads (see images below for more details). To be honest I’ve never thought for a moment about the seal rings or threads on any bottles or jars around the house, but I challenge you to take a closer look next time for yourself to see the variation of design and construction!

(Forced) Innovation

Over the decades, the Nalgene brand popularity grew as reusable water bottles became more commonplace. However, in the mid 2000s, reusable drinking bottle manufacturers started facing a series of questions and challenges about the potential health impacts of the bisphenol (BPA) found in the polycarbonate materials. Scientific studies were suggesting BPA could interfere with endocrine (hormone) systems and was linked to illness and even cancer.

Not surprisingly, Nalgene claimed the product to be safe, particularly when used within standard temperature ranges. Also not surprisingly, retailer and consumer concerns persisted.

In 2005, outdoor retailer Patagonia was one of the early movers and pulled drinking bottles that contained BPA from stores. Then in 2007, Canadian outdoor retailer Mountain Equipment Co-op and Lululemon removed all clear polycarbonate water bottles from their shelves and replaced them with BPA-free bottles. A year later, the Canadian government proposed adding BPA to the toxic materials list and banned its use from baby bottles.

Finally the combination of retailer/consumer pressure and government regulation forced Nalgene to act. In 2008, Nalgene started manufacturing their bottles with a new BPA free material developed by Eastman Chemical, called Tritan (see footnote for more information). Tritan is now used in dozens of common household goods by leading consumer brands like Vitamix, Magic Bullet and Cuisinart. Eastman Chemical lists 44 water bottle brand partner companies that use the same Tritan material, including Nalgene, Thermos and Camelbak.

Sustainability

Today, Nalgene makes ~20,000,000 bottles per year out of their factory in Rochester, New York. They source their raw material, plastic (Tritan) pellets, from Eastman Chemical in Tennessee, and calculate this domestic sourcing and local production results in a 90% smaller carbon footprint than sourcing and shipping from overseas. At the Rochester plant, colours are mixed with the plastic and then injection blow molded (inflated like boiling hot plastic balloons) into the classic 32 oz silhouette. The lids, straps, and buttons are all made in the same facility. Screen printed labels are added on too. Sounds like a pretty simple ‘made in USA’ manufacturing story. But wait, what about the Tritan?

Perhaps like many chemical companies, Eastman (and Nalgene) offer limited consumer-friendly transparency into how exactly Tritan material is made at their plant in Tennessee. To be fair, as a non-Chemical Engineer, I have no idea how many things around me are actually made. The materials in my smartphone, car or fridge? No idea. However, based on what I think I know, I have cognitive dissonance when I consider the sustainability of durable products made from polymer (petroleum) based materials. A non-renewable resource (petroleum) is extracted and processed in a black-box… and then out comes a “wonder material” whose properties and performance are superior to “simpler” and more “natural” materials like wood, glass or perhaps even steel. But at what true cost?

That being said, once Tritan is made, it’s damn tough and hard wearing, resulting in a very long expected life. There’s no shortage of stories about how Nalgene bottles have survived drops, whitewater canoe trips or even being driven over by a car. If a Nalgene bottle does somehow break, the Tritan material is labeled as a #7 plastic and is accepted by an increasing number of local recycling programs. You may even qualify for a replacement under Nalgene’s lifetime warranty.

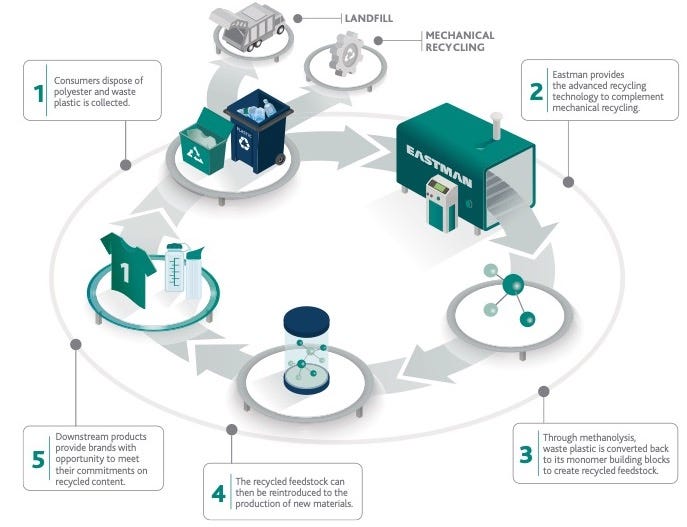

And of course, the story of Nalgene’s material innovation isn’t over yet. In 2020, Nalgene introduced their “Nalgene Sustain” line of bottles made from a new variation of Tritan named Tritan Renew. This new material claims to deliver all the same functionality as the original Tritan but is made from 50% certified recycled content. Tritan Renew is the result of Eastman’s commitment to developing “advanced circular recycling” processes and materials. Eastman has stressed how important of a breakthrough this process is, as they aren’t simply recycling materials that would normally be recycled into other products, but they are using “chemistry to break down (single use) waste plastics into molecular building blocks that can be reused”. I’m curious to see how quickly production of this material will be scaled and what percentage of Nalgene consumers are willing to pay the 20-25% price premium. It's an exciting step in the direction of more sustainable practices.

Value

For me, anything that is a timeless design, costs $10-20 and could be used daily with a lifetime guarantee is a winner. Sure, it’s more expensive than a simple drinking glass... but it won’t break. And it’s cheaper than most stainless steel alternatives...and it won’t dent or retain strong flavours like coffee.

Even if you’re looking for a deal, you probably want to avoid the second hand market unless you can verify the bottle was produced after 2008 to avoid old materials with BPA risks. But, if you’re really looking for a deal and don’t mind something that is non-Made-In-USA, “Maars” sells a similar looking 34oz bottles made with Tritan on Amazon for as low as $7/bottle.

One of the great things that is often common with design classics is the availability of replacement parts. They can help extend the useful life of an object, reduce waste and increase the overall value proposition. I don’t usually expect plastic objects to be repairable, or have replacement parts, especially when they are sub-$20 items, but Nalgene stands out as an exception. With the Nalgene bottle’s simple and consistent four piece design and construction (bottle, lid, button, strap) it lends itself to easy cap replacement, which Nalgene is happy to sell for only around $5.

If you’re less budget conscious and looking for a bit of hype, Jared is a fan of co-branded Nalgene water bottles from the likes of Online Ceramics, JJJJound, Glossier and others. If your local outdoor gear store has their own branded Nalgenes, that’s a great way to show your support. Or you can always just slap a sticker on it!

Hope you enjoyed this! Hit reply or leave a comment and let us know. If you have anything you want us to look into, just let us know (and why)!

A footnote on Eastman Chemical’s Tritan

In the early 2000s, Tennessee-based Eastman Chemical was working on developing a new plastic material that would have superior performance to existing polycarbonates. Although Eastman didn’t have a specific customer application in mind, they believed the success of a new material would be dependent on delivering on four key characteristics: “clarity” (for looking good), “durability”, “processability” (customers could easily retool existing equipment to work with the material) and “heat resistance”. In 2003, their early testing of a new copolyester material showed it “could endure 500 dishwashing cycles, with no sign of damage whereas polycarbonate would start to crack after a few dishwashing cycles”. BINGO. By 2007 Eastman introduced a new “BPA free” plastic material called Tritan. Inherently “tough, clear, high-temperature, chemically resistant and also dishwasher resistant”, it had all the features of Nalgene’s polycarbonate, but without the concerns of BPA...and it could handle the dishwasher.

Since launching Tritan in 2007, Eastman has had to deny claims by some scientists that the material is “harmful to humans” and has “estrogenic activity” (similar to BPA). They have defended their safety claims based on research by “accredited universities and independent third-party labs (that) used well-recognized scientific methods”. In 2013, Eastman went to court and won a court ruling against a company that had claimed Tritan was harmful, and the “safety of the material was upheld”. For what it’s worth, Eastman highlights that, “Multiple government regulatory and standards agencies have approved the use of Tritan from Eastman in food contact products. These agencies include Health Canada, U.S. Food and Drug Administration, European Food Safety Authority, European Commission, China’s Ministry of Health and Japan Hygienic Olefin and Styrene Plastics Association.”

Great article! As someone who has used Nalgene products in both the lab and field, I can totally attest to the products’ utility and dependability. We’re on generation three now for Nalgene useage in our family and so the enduring legacy continues...Nalgenes (filled) also make for great counterweights to get food barrels up into a tree. What’s also amazing is that the breadth of water filtration systems available now for campers have been designed for compatibility specifically to the 32 oz Nalgene bottles.

hi kevin, terrific article! would you be able to share the source where you found the old Nalgene advertisement? i'd love to reproduce for a book on the history of camping, in which there's a chapter on water and campgrounds. Thanks!